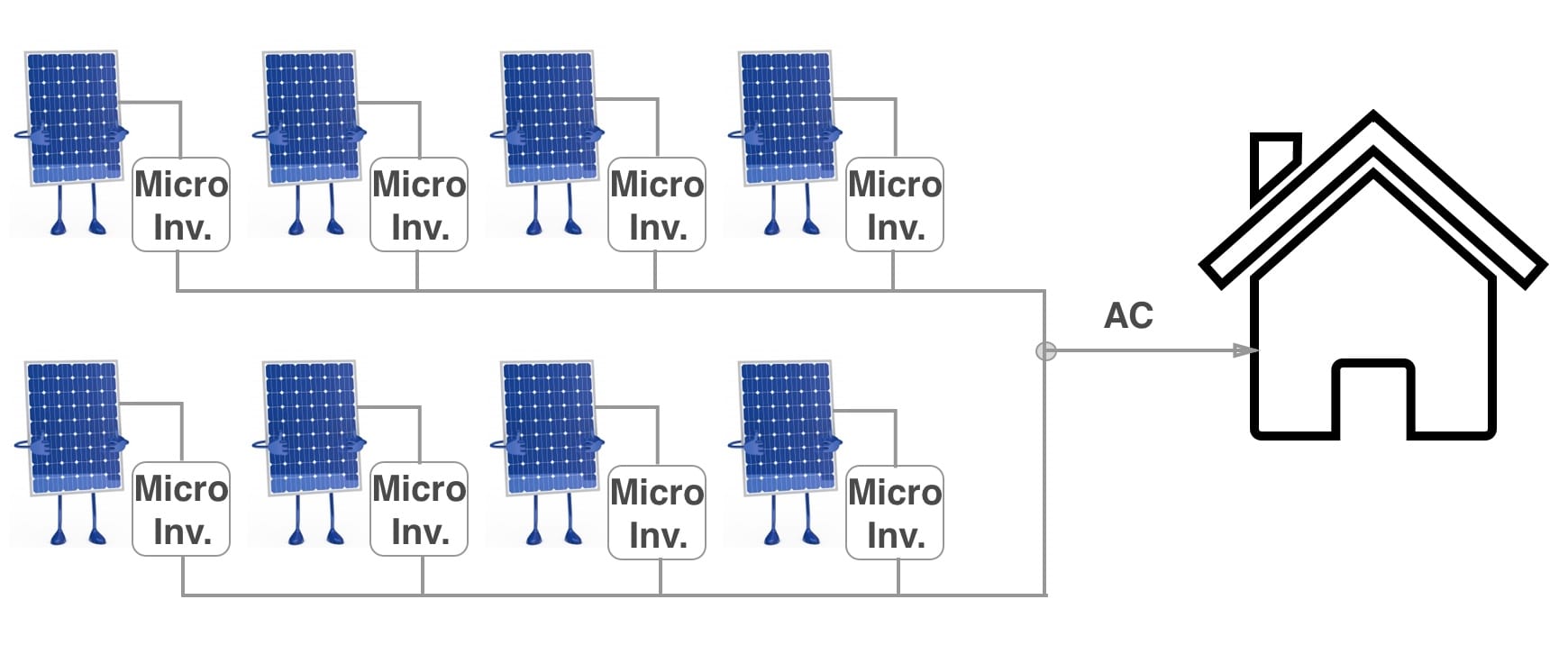

Micro-inverters are a type of solar inverters that tie to each panel individually and convert DC produced by that panel into AC. The outputs from all the micro-inverters are then combined to be consumed by various electric loads. Micro-inverters can have a monitoring device which can log performance metrics and errors for each inverter and wirelessly send the data to the manufacturer server to be displayed online or the data can be stored locally. When opting for this monitoring feature make sure to check whether the manufacturer charges for the service.

Micro-inverters VS String Inverters

String inverters perform electrical current conversion from DC to AC. Unlike micro-inverters string inverters just string together all the PV modules and if one module's energy generation suffers (because of partial shading for example) then the whole system's output is compromised. Unlike string inverters, micro-inverters do not have a single point of failure. They can control the output of each module and cooperate to squeeze the maximum power from the PV system even if some panels are shaded. As you may imagine string inverters are bulkier and heavier than micro inverters. A typical microinverter's dimensions are 6.7" x 6.7" x 1.3" (170mm x 170mm x 30mm) and the weight is 4.4 lbs (2 kg). String inverters typically weigh 62 lbs (28 kg) and the dimensions are 14" x 26" x 8"(360mm x 650mm x 200mm)

Advantages of Micro Inverters

If you happen to have a PV panel installation where panels face different directions or some of the panels are shaded then micro-inverters are your best bet in these situations. If one of the micro-inverters stops operating or if its wire is cut the system as a whole continues to operate whereas in case of string inverter if one wire in the series of connected wires is damaged the system as a whole stops functioning.

Another valuable advantage of a micro-inverter is that it doesn't require all the PV panels to be of the same characteristics and lends itself to a modular design. So let's say you have a PV system installed on your roof with micro-inverters connected to the panels. After some time you may need more power and decide to add more panels. You can do it easily by adding new inverters and what's interesting the new PV modules don't have to be the same as the previously installed modules. New modules can have different brands and characteristics.

Micro-inverters directly connect to a PV module with low-voltage DC wires. This eliminates the danger of electric shock to the installation personnel because of high DC voltage.

Drawbacks of Micro Inverters

So micro-inverters are physically attached to the back of a PV and we know that PV panels can get very hot. Besides micro inverters can themselves get hot because they make DC to DC conversion then DC to AC conversion. The temperature can rise up causing a damage to micro-inverters and they can potentially fail. Some manufacturers have come up with a solution to split up some of the electronic components inside the micro inverter to avoid the mentioned issue. A company called SMA has introduced a new component in the system called multi-gateway. Their micro-inverters do the usual MPPT and optimizations and the produced AC is then directed to a device called multi-gateway(MG) through a common base. AC from the MG output is then sent to the house. The objective of this change is that some electronics are removed from micro-inverters and moved to MG thus reducing the risk of overheating. However, this new system also has its trade-offs because MG introduces a point of failure for the system.

Costs

While micro-inverters have higher combined cost compared to a single string inverter it's actually arguable whether they drive up the cost of the whole system. The catch is that a system with micro-inverters eliminated the design costs as opposed to its counterpart with string inverter and the wiring costs can also be significantly lower. An added benefit is that power production of micro-inverters is reported to be 5% - 20% higher than that of string inverters. To compare the overall cost of the system a term dubbed Levelized Cost of Energy (LCOE) is introduced. LCOE takes the complete cost of each system and the energy produced by each system during its lifetime (say 25 years) and calculates the cost per unit of energy ($/Wh). This calculation itself poses a challenge because each installation is different and there are many factors at play when trying to calculate the total produced energy of a system.

Enphase M215 Micro-inverter

Main Features:

- Integrated ground

- No Ground Electrode Conductor (GEC) is required

- Integrated with Enphase Enlighten monitoring and analysis software

- Ambient temperature range: -104 F to +149 F (-40 C to +65 C)

- Dimensions: 6.7" x 6.8" x 1.2" (171mm x 173mm x 30mm)

- Weight: 3.4 lbs (1.6 kg)

- Up to 25 years of warranty

M215 comes with a communication device called Envoy. What it does is collect production and performance data over AC lines and transmits data to Enlighten for displaying. Envoy is capable of monitoring up to 600 microinverters. Enlighten is a web-based software that displays the obtained detailed metrics stored on the server. Enlighten can be used to manage multiple PV systems and remotely resolve issues that may arise during their operation. Enphase has developed an iOS and Android mobile apps that allow the installation specialists to configure the system while onsite. The apps eliminate the need for a laptop and increase installation efficiency. Mobile apps allow a) wireless connection to Envoy for the system setup and verification. b) viewing of installation summary report and emailing the report c)confirmation of a successful installation d) syncing with Enlighten monitoring software. M215 micro-inverter ships with the necessary AC and DC cables.

| Input (DC) | |

|---|---|

| Max DC Voltage | 48V |

| Operating range | 16V - 48V |

| Commonly paired module Wattage | 190 - 270+ W |

| Output (AC) | @208VC | @240VAC |

|---|---|---|

| Peak Output Power | 225W | 225W |

| Nominal Voltage | 208V | 240V |

| Nominal Frequency | 60Hz | 60Hz |

Enphase IQ7-60-2-US Micro-inverter

Main Features

- Smart grid-ready

- Improved, lighter two-wire cabling

- Built-in rapid shutdown

- Optimized for high-powered 60-cell and 72-cell (IQ 7+) modules

- Double-insulated enclosure

- Ambient temperature: -104 F to +149 F (-40 C to +65 C)

- Dimensions: 8.3" x 6.9" x 1.2" (212mm x 175mm x 30mm)

- Weight: 2.38 lbs (1.08 kg)

The 7th generation of Enphase IQ series generates 4% more energy and is 19% lighter than IQ 6 series. Compared to M215 micro-inverters IQ7 series inverters can pair with PV panels of higher wattage output. IQ 7 series micro-inverters also have higher peak output power. Works with Enphase IQ Envoy for data collection and Enphase IQ Battery for backup. In contrast with Enphase Envoy which only supports LAN connections, IQ Envoy has integrated Wi-Fi and optionally supports 3G or 4G connections.

| Input (DC) | IQ7 60 | IQ7 Plus 72 |

|---|---|---|

| Max DC Voltage | 48V | 60V |

| Operating range | 16V - 48V | 16V - 60V |

| Commonly paired module Wattage | 235 - 350+ W | 235 - 440+ W |

| Output (AC) | IQ7 | IQ7+ |

|---|---|---|

| Peak Output Power | 250VA | 295VA |

| Nominal Voltage | 240V | 240V |

| Nominal Frequency | 60Hz | 60Hz |

Comments