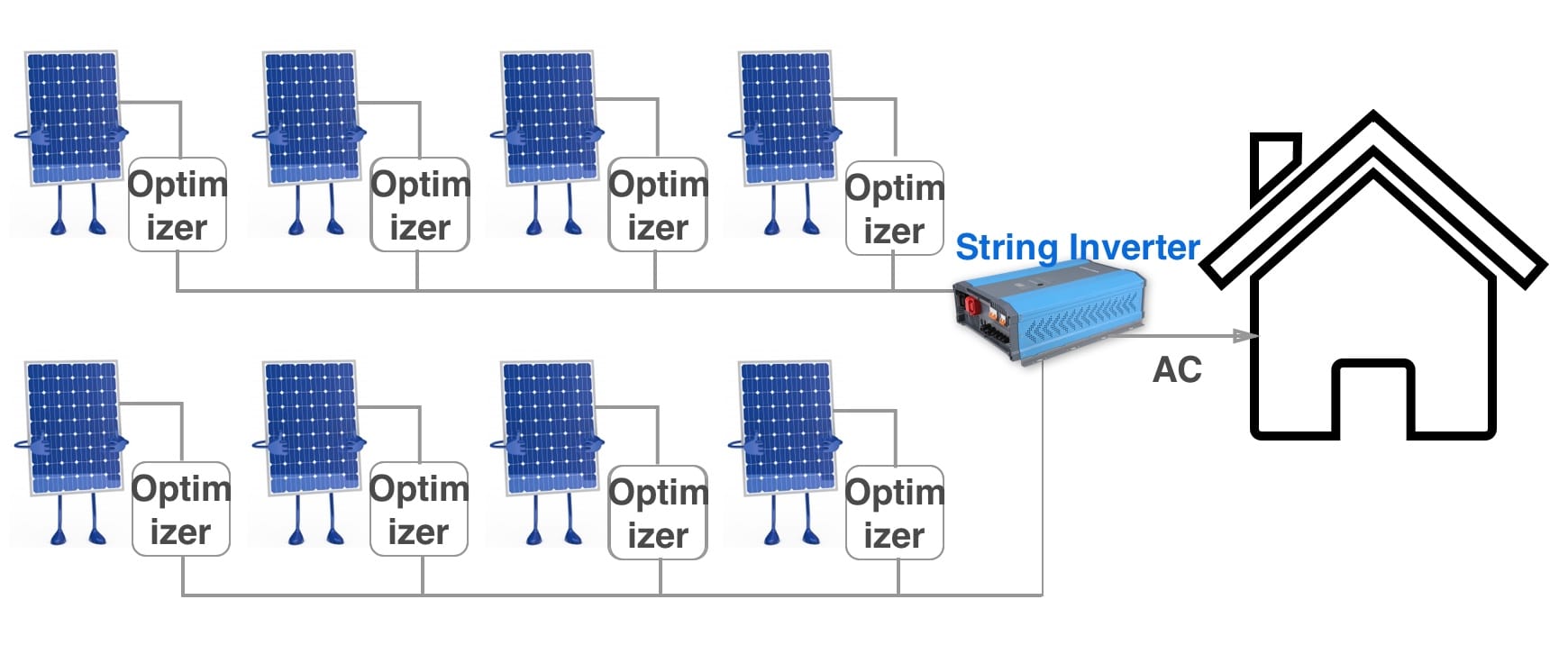

Solar power optimizer or DC optimizer is a DC to DC conversion device mounted on each PV module to optimize power output. It employs the MPPT (Maximum Power Point Tracking) algorithm to do the optimization. The outputs from power optimizers are tied to a string inverter which lacks MPPT or has it disabled. Unlike the case when panels are directly connected to a string inverter the system with power optimizers is not susceptible to decreased power production due to shading or a lower rated output of a single module.

Power optimizers bring design flexibility. Modules are no longer constrained to form a single surface but can be rotated and tilted towards the direction of maximal sunlight absorption. Strings can also be of various lengths. Power optimizers are a more cost-effective alternative to micro-inverters. They also connect to individual panels but unlike micro-inverters, they don't directly convert Direct Current into Alternating Current but rather modulate the output of a panel and send it to a string inverter. This typically yields a higher system efficiency than a string inverter could have provided alone.

MPPT

Solar panels have a complex relationship between the power they produce, the load on them and the efficiency of the produced power. Because a range of factors like the time necessary to generate an electrical charge when a light photon hits its surface, ambient temperature and so on there is no straightforward relationship between voltage, current and the power produced by the panel. To tackle this issue a technique is devised to continuously track the voltage and adjust the load so that at a given time a single panel or an array of those is at its peak efficiency point.

String inverters, micro-inverters and power optimizers alike have MPPT embedded. The difference is that string inverters look at a PV array as one whole module and the array's lowest productive module compromises the whole system. Micro-inverters and power optimizers distribute MPPT to 1, 2 or 3 modules at a time making the system more robust.

Power Optimizer vs Micro Inverter

Power optimizers sit between string inverters and micro-inverters. They do optimizations based on MPPT as micro-inverters do but unlike micro-inverters, they don't do DC to AC conversion. Because power optimizers are less complicated devices than micro-inverters they typically cost less. Module level power optimization is reported to bring about 5% - 25% increased power production.

Power Optimizer Mounting

There are 3 ways power optimizers can be mounted on the back of a module:

- The optimizer is attached on the junction box by the installation personnel onsite.

- The optimizer is pre-mounted on the module frame during the production process

- The optimizer is embedded by the PV module manufacturer replacing the junction box

SolarEdge Power Optimizers

These optimizers provide MPPT, module-level monitoring, and safety shutdown. We have discussed above how MPPT works now let's see what module-level monitoring can give you. Basically, the performance metrics can be transmitted to SolarEdge servers wirelessly. When the data is stored on the server you can have a web-based display of your PV array's current state. You can see the location of an underperforming module (if any) on a virtual sitemap. You can also view the performance charts for a chosen period of time. If for some reason the system is disconnected from the grid or the central inverter is down then power optimizers cut off the current and voltage.

SolarEdge power optimizers are also capable of arc detection and termination. What is an arc detection you would ask? Power production alternates between periods of peak and nominal output. Such a pattern, building up over time, can strain the cables and connections bringing about weak parts in insulation and loosening up the wires. This process can cause electrical arcs. As a result, short circuit and overloading can occur.

Main Features:

- Fast installation with a single bolt

- MPPT range: 8 to 80 VDC

- Connector: MC-4 type

- Warranty: 25 years

SolarEdge provides a wide range of power optimizers depending on PV module power. Below you will find a table of the available power optimizer models with corresponding PV module type and rated power. When combined with SolarEdge inverters power optimizers can maintain a consistent string voltage even when one of the panels is shaded or the sunlight is otherwise obstructed for a part of the panels. When the voltage of one of the panels drops due to shading inverter slightly increases the output voltage for the rest of the power optimizers thus mitigating the negative impact of the shaded panel. This gives the installers a greater flexibility in using various length strings for the optimal layout of the system. SolarEdge power optimizers are compatible with crystalline silicon, thin-film, and high current PV modules

| Power Optimizer Model | PV Module Power | PV module Voc | PV Module Compatibility |

|---|---|---|---|

| P300 | ≤ 300W | ≤48V | 60-cell modules |

| P370 | ≤ 370W | ≤60V | High power 60-cell and 72-cell modules |

| P500 | ≤ 500W | ≤80V | 96-cell modules |

| P404 | ≤ 405W | ≤80V | 60-cell and 72-cell, short strings |

| P505 | ≤ 505W | ≤83V | High current modules including bi-facial modules |

| P405 | ≤ 505W | ≤125V | Thin film modules |

PV module Voc in the above table is the open current Voltage of the module. That is the voltage measured on the module when it has no connected loads. You would expect to see it indicated on the module's specification sheet.

First 4 models are optionally available with frame mounted bracket for faster installation. P405 model for thin films has 2 inputs for parallel connection of 2 modules. Single input version is also available.

Commercial Grade Power Optimizers

Power optimizers for commercial solutions connect to 2 PV modules each for reduced costs.

| Power Optimizer Model | PV Module Power | PV Module Voc | Typical Module Compatibility |

|---|---|---|---|

| P600 | ≤600W | ≤96V | 2 x 60-cell PV modules |

| P700 | ≤730W | ≤125V | 2 x 72-cell PV modules |

| P800p (for parallel connection) | ≤800W | ≤83V | Parallel connection of 2 x 96-cell 5’’ PV modules |

| P850 (for series connection) | ≤850W | ≤120V | Series connection of 2 x high power or bi-facial modules |

In the above table PV Module Power is the value of the combined power of 2 modules connected in series under standard test conditions. P800p model contains 2 inputs for parallel connection of modules.

Comments