We decided to cover heat pumps in detail because they embody energy efficiency principles and can also run on solar! If you are not familiar with these ingenious heaters yet, you'll find extensive information about all aspects of heat pumps in this article. To start with, heat pumps need much less operating energy compared to older electric resistance heaters. They can serve for both heating and cooling purposes. Heat pumps move the thermal energy in the opposite direction of natural heat transfer: they take heat from a colder environment and move it to a warmer space.

Heat Pump Basics

Heat pumps do not create heat through the burning of fossil fuels or resistance like the conventional electric heaters. A heat pump relies on external power to fulfil the task of transferring the heat from the source to the heat sink, that is, the conditioned space. It makes the warm space warmer and the cool space cooler. This is exactly what you need for heating or cooling your room. The typical design of a heat pump involves four main components:

- a condenser

- an expansion valve

- an evaporator

- a compressor

The heat transfer takes place through a chemical component called refrigerant.

Coefficient Of Performance (COP)

A heat pump's performance is measured under standard conditions as the "coefficient of performance": this measures the ratio of heat output in relation to the electrical input. Note, however, that CoP is considerably influenced by the output temperature delivered to the heat distribution system in the building and the input temperature from the heat source.

In winter, a ground source heat pump with access to a temperature of 50°F (10°C) from the ground will deliver a significantly higher CoP than an air source heat pump with access to 14°F (-10°C) from ambient air. The design, installation quality, and controls of a ground source heat pump installation are crucial for achieving good performance.

How does it work?

When a heat pump is used for heating, it employs the same basic refrigeration-type cycle used by an air conditioner or a fridge, but in the opposite direction – releasing heat into the conditioned space rather than the surrounding environment. In this use case, heat pump AC generally draws heat from the cooler external air or the ground.

All HVAC systems including heat pumps rely on refrigerant's pressure-temperature relationship. When a refrigerant evaporates or boils it absorbs heat at a rapid rate as is the case with all liquified gases. Since a refrigerant has a lower boiling point than most liquids we can easily manipulate it so that the only heat source needed is room temperature air. We can control this boiling point by altering the pressure placed upon the liquid.

Below we go into greater details of operation for each type of heat pumps. We also describe how various types of compressors work so keep reading or use the table of contents above to quickly navigate to the desired section.

Components

The components of the heat pumps are the same as the refrigerator or the air conditioner, the only difference is that they work in a reverse manner. Hence the heat pump is also called a reverse refrigerator. There are four important components of the heat pump: compressor, condenser, expansion valve, and the evaporator.

Compressor

There are 4 main types of compressors used in the heat pumps: centrifugal, screw, reciprocating, and scroll. Let's look at each of these types at greater detail.

Centrifugal compressors

Most centrifugal applications in heat pumps have been limited to large water-to-water or refrigerant-to-water heat pump systems, heat transfer systems, and storage systems. With these applications, the centrifugal compressor allows heat pump use in industrial plants, as well as in large multistory buildings.

The Working Principle

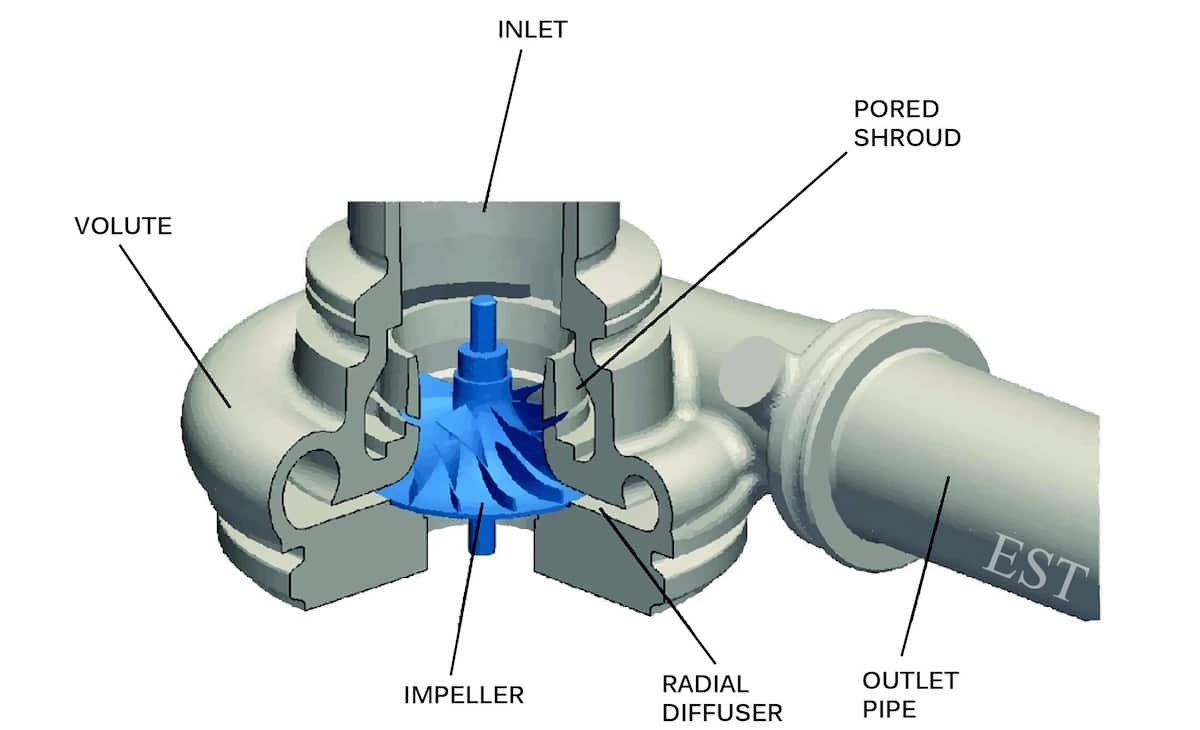

Centrifugal compressors use non-positive displacement vapour compression for compressing large amounts a refrigerant. The main components of a centrifugal compressor are a rotor (impeller), a diffuser and a volute casing. Large-capacity centrifugal compressors may have 2 or more impellers or stages in the same casing. The rotor consists of vanes or blades and the entire rotor is mounted on the hub. The rotor is placed inside the casing. So the rotor is driven at high speed by the electric motor. As the impeller rotates it moves the refrigerant vapour from the suction opening in its center to the outer edge using centrifugal force. The vapour enters the suction at a relatively low velocity and leaves the outer edge of the impeller at a higher velocity. But high velocity doesn't relate to high static pressure. That's where the diffuser comes in. As the high-velocity vapour moves radially outward through the diffuser the flow area increases slowing the vapour and increases the static pressure. Finally, the volute-shaped casing collects the high-pressure, slow-moving vapour from around the diffuser and conveys it to the discharge connection of the compressor.

Screw compressors

Screw compressors offer high-pressure ratios at low to high capacities. Capacity control is usually provided by variable porting or sliding vanes. Generally, large oil separators are required, because many compressors use oil injection.

The Working Principle

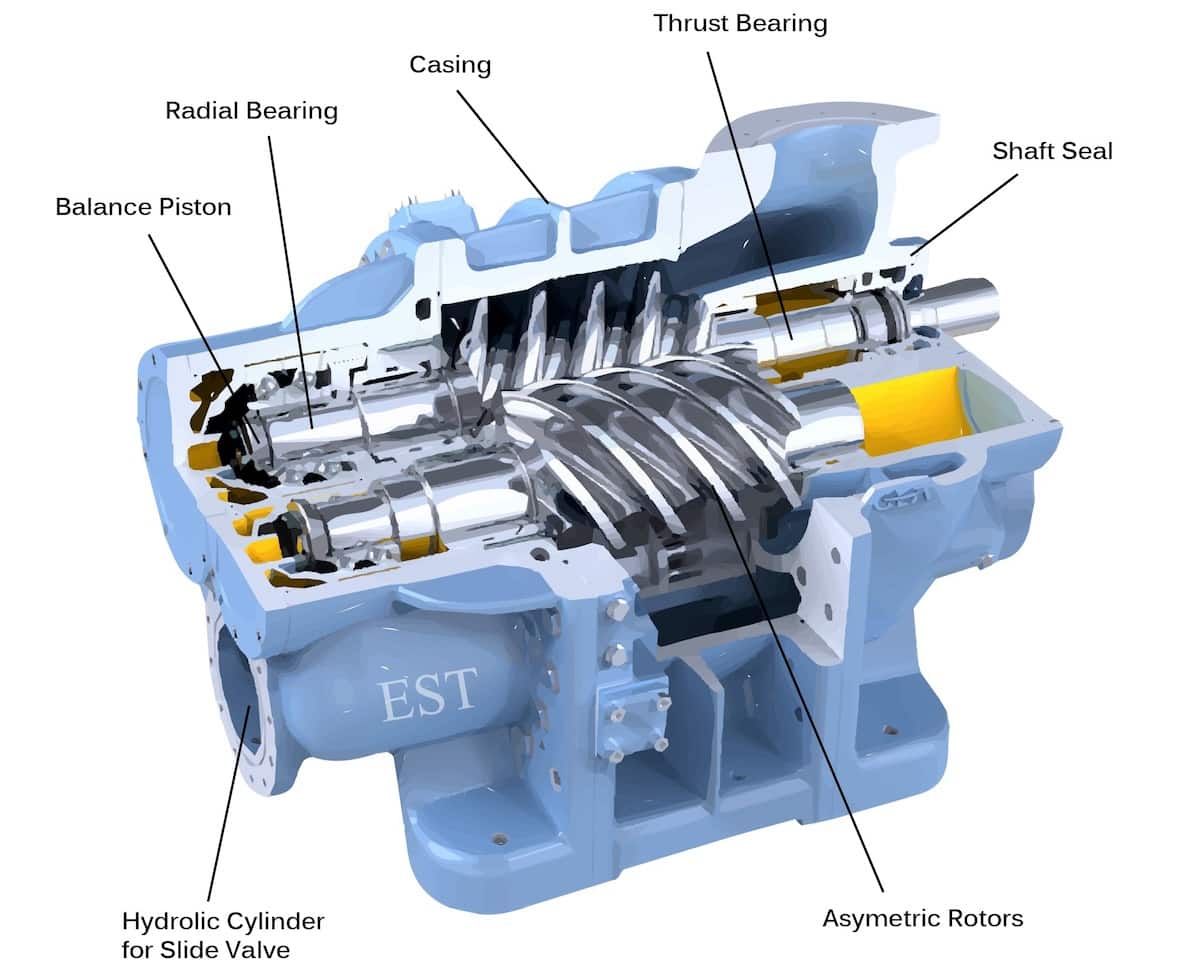

All screw compressors operate according to the basic principle of positive displacement machine whose key element is a pair of spiral rotors. During operation, the rotors turn and the spiral teeth mesh together forming chambers between the rotors and the casing wall. Rotation causes the chambers to move from the suction or intake side to the compression or discharge side. These chambers are connected to the suction nozzle via ports. As the chambers enlarge they are filled with refrigerant flowing in through the nozzle. To better understand the process let's look at an individual chamber. It enlarges, is filled with the refrigerant and then closed by a circumferential edge in the casing. The rotors now transport the refrigerant to the discharge side where the chamber shrinks and the retained refrigerant is compressed. Once the refrigerant is compressed the chamber reaches another port connected to a discharge nozzle and the compressed refrigerant flows out.

In fact, all the chambers between the 2 rotors are being filled and emptied continuously. This means that with a screw compressor the compression process is more or less ongoing. The design of a screw compressor combines the advantages of a positive displacement machine with those of a rotating machine making this type of compressor suitable for a wide range of applications.

Reciprocating compressors

These compressors are the most common for 1.8 to 350 kW systems.

The Working Principle

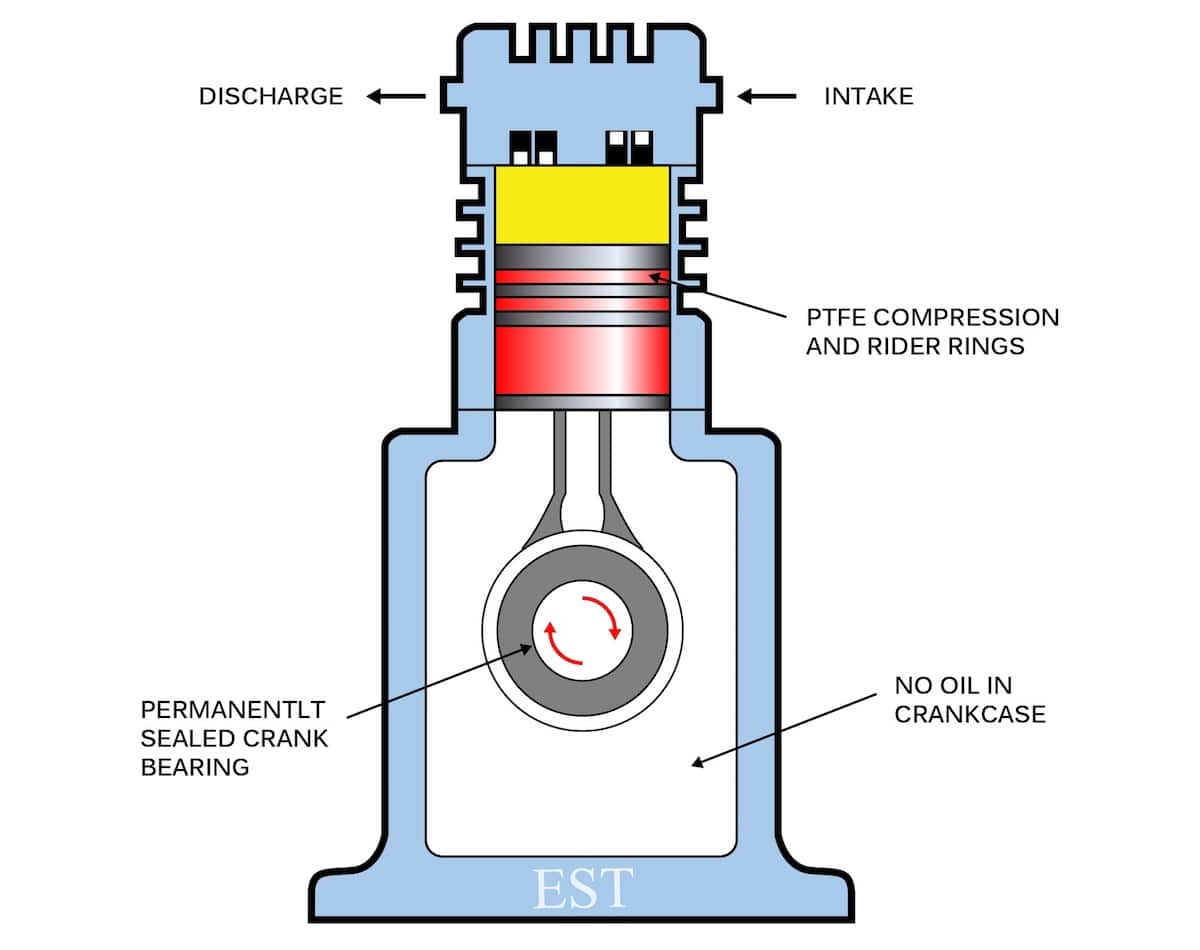

A reciprocating compressor compresses refrigerant vapour in a cylinder using a piston. In a way, reciprocating compressors are like car engines: the pistons are directly driven through a wrist pin and connecting rod from a crankshaft. Depending on their size, reciprocating compressors may have 1 or more cylinders. Multiple cylinders might be arranged in a line, opposed or in a V shape. In each cylinder, reciprocating compressors have both a suction valve and discharge valve. These valves give the compressor its ability to pump refrigerant vapour against a pressure difference. They are usually located in the head of the cylinder, in passages connected to the high or low-pressure side of the system. Let's follow the compression process in the single-cylinder reciprocating compressor during one complete revolution of the crankshaft. Starting with the piston at the top of its stroke or at the top dead center the piston begins to move downward as the crankshaft rotates. Because both valves are closed the downward moving piston reduces the pressure in the cylinder. As the pressure in the cylinder falls below the low side pressure in the suction line the pressure difference opens the suction valve letting the refrigerant vapour flow into the cylinder. The piston continues down and pulls in more vapour until the cylinder is filled with low-pressure vapour at the bottom of its stroke. Once past bottom dead center the piston begins its upward stroke, the suction valve closes. As the piston moves up it reduces the volume of the space in the cylinder increasing the pressure of the vapour. When the pressure in the cylinder exceeds the high side pressure in the discharge line the pressure difference pushes the discharge valve open letting the compressed vapour flow out of the cylinder. This continues until the piston reaches the top of its stroke and most of the compressed vapour has been expelled into the discharge line. When the piston begins its downward stroke the discharge line closes, the complete cycle then repeats during the crankshaft's each revolution. This is the mechanical positive displacement vapour compression cycle a reciprocating compressor.

Scroll compressors

These are a type of orbital motion positive displacement compressor. Their use in heat pump systems is increasing. Their capacity can be controlled by varying the drive speed or the compressor displacement. Scroll compressors have low noise and vibration levels.

The Working Principle

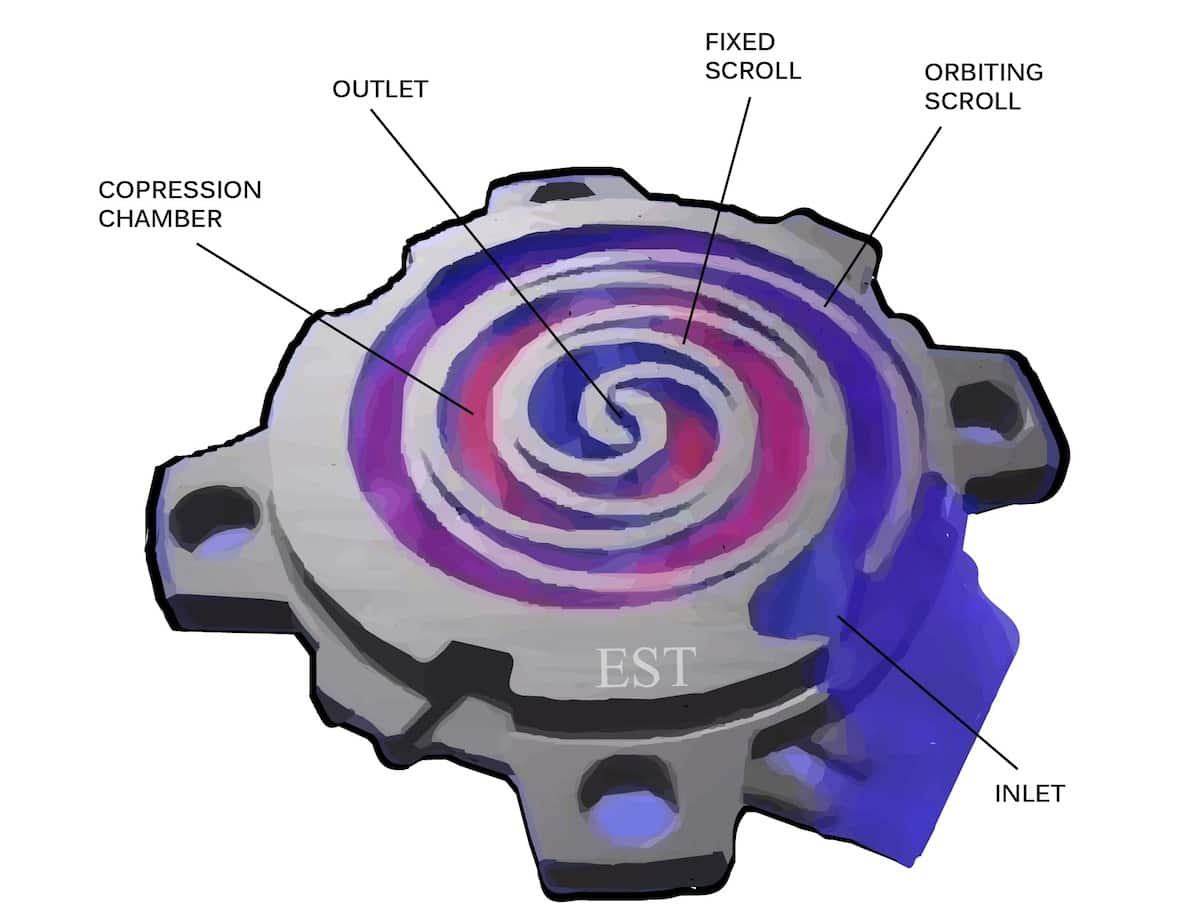

A scroll compressor, aka scroll pump, consists of a shell with an inlet and an outlet. The lower part of the shell contains a lubricant which is used, for example, to lubricate plain bearings. A motor sets an Archimedean scroll in motion. The scroll is located in the shell's upper part. The scroll housing has an inlet as well as a discharge port and fixed scroll. The scroll housing has a base plate. The fixed scroll is attached to the underside of this base plate. The refrigerant vapour is absorbed in the forming chambers and transported to the center of the scroll set. As the rotation progresses the chambers become much smaller so that the vapour is compressed within the compressor. Therefore, this type of compression is called internal. In the middle of scroll housing, there's a discharge port through which the compressed gas can escape. Normally, there's also a check valve.

There are two common scroll compressor designs. In the first case, the movable scroll moves on the extremely small distance from the other scroll. The scrolls, therefore, do not touch each other. The second design involves scrolls that are in contact. Such scroll compressors have a better seal and thus higher efficiency. The small number of moving components make scroll compressors highly reliable in operation.

Condenser

A condenser is a unit used to condense a substance from its gaseous to its liquid state by cooling it. In heat pump systems the substance is the refrigerant. The latent heat released during the cooling process is transferred to the surrounding environment or to the water, in case of heat a pump water heater. Condensers can be made according to quite a few designs, and come in many sizes ranging from rather small (hand-held) to very large (industrial-scale units used in plant processes).

Expansion Valve

The expansion valve is the pressure reducing device. When the high pressure and medium temperature refrigerant enters the expansion valve its pressure reduces suddenly and along with it its temperature also becomes very low suddenly. The expansion valve most commonly used in the heat pumps is a copper capillary tube. The refrigerant leaves the expansion valve at extremely low pressure and low temperature in partially liquid state and partially gaseous state.

Evaporator

Depending on the heat pump's mode of operation (heating or cooling), the evaporator can be either the outside or the indoor coil. In the winter mode, the evaporator is located outside the room and exposed to the atmosphere at very low temperatures. Just like condenser, the evaporator is also made up of copper coil. The low pressure and low-temperature refrigerant enter the evaporator coil, due to this the temperature of the coil also reduces drastically and it becomes even lower than the atmospheric temperature. Since the refrigerant's temperature is lower than the outside temperature it tends to absorb heat from the atmosphere. The fan facilitates this process. The heat is then brought inside to heat the indoor air.

In the summer mode, the indoor unit's coils act as an evaporator. The refrigerant's cold and low-pressure liquid-gaseous mixture evaporates while absorbing heat from the passing indoor air. The refrigerant then travels to the compressor where the process is repeated.

Sizing A Heat Pump

Heat pumps are measured by BTUs (British Thermal Units) they produce when in cooling mode. The most popular sizes purchased by homeowners are 9k BTU, 12k BTU, 15k BTU, 18k BTU. There's a direct relationship between the area of your house and the heat pump size. Other important factors when choosing a heat pump are insulation and building orientation. It is always a good idea to do a home energy audit and act upon the recommendations outlined in the energy audit report before choosing a heat pump. That's because a drafty house will require an unnecessarily upsized heat pump.

Outdoor ambient temperature may also play a big role in the selection process. With the outdoor temperature drop, the heat pump's output capacity also drops. Consequently, a larger sized heat pump will be required to heat a house in an area with colder winters compared to a same-area house located in an area with milder winter.

If what you need is a ballpark estimate then here's a quick table showing the relationship between the heat pump size and the area of the house not taking into account the other factors discussed above.

| Heat Pump Size (BTU) | House Area (sq f) |

|---|---|

| 9,000 | 250 - 450 |

| 12,000 | 550 - 800 |

| 15,000 | 750 - 1100 |

| 18,000 | 850 - 1250 |

Heat Pump Types

Air Source Heat Pumps

Air Source Heat Pumps (AHSP) are electric appliances that provide heating by moving thermal energy from outside air to inside air. Outdoor air is a universal heat source and sink medium for heat pumps and is widely used in residential and light commercial systems. A refrigerant that absorbs heat cycles through the system. The 2 categories of air source heat pumps are:

Air-Air Heat Pumps

This is the most common type and is widely used in residential and commercial applications. They transfer heat from outside air to inside air. These are also known as heat pump ACs because they are similar to air conditioners operating in reverse. In air-to-air heat pump systems, air circuits can be interchanged by motor-driven or manually operated dampers to obtain either heated or cooled air for the conditioned space. In this system, one heat exchanger coil is always the evaporator, and the other is always the condenser. Conditioned air passes over the evaporator during the cooling cycle, and outdoor air passes over the condenser. Damper positioning causes the change from cooling to heating.

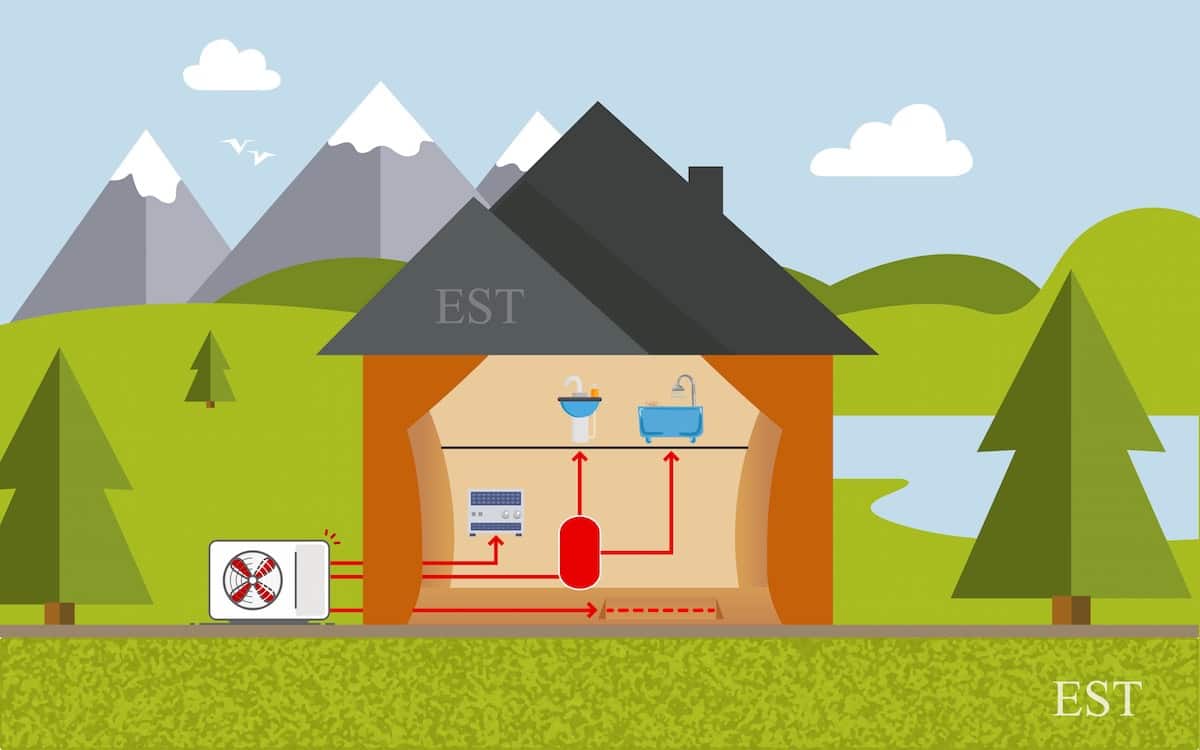

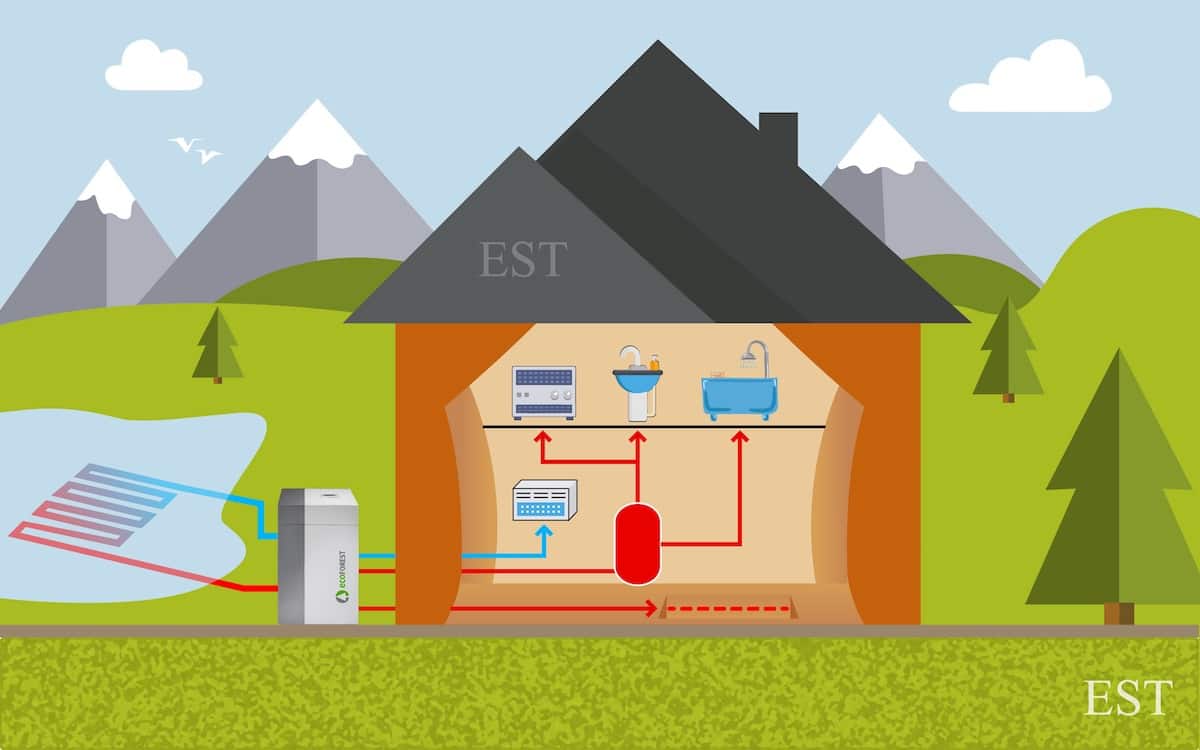

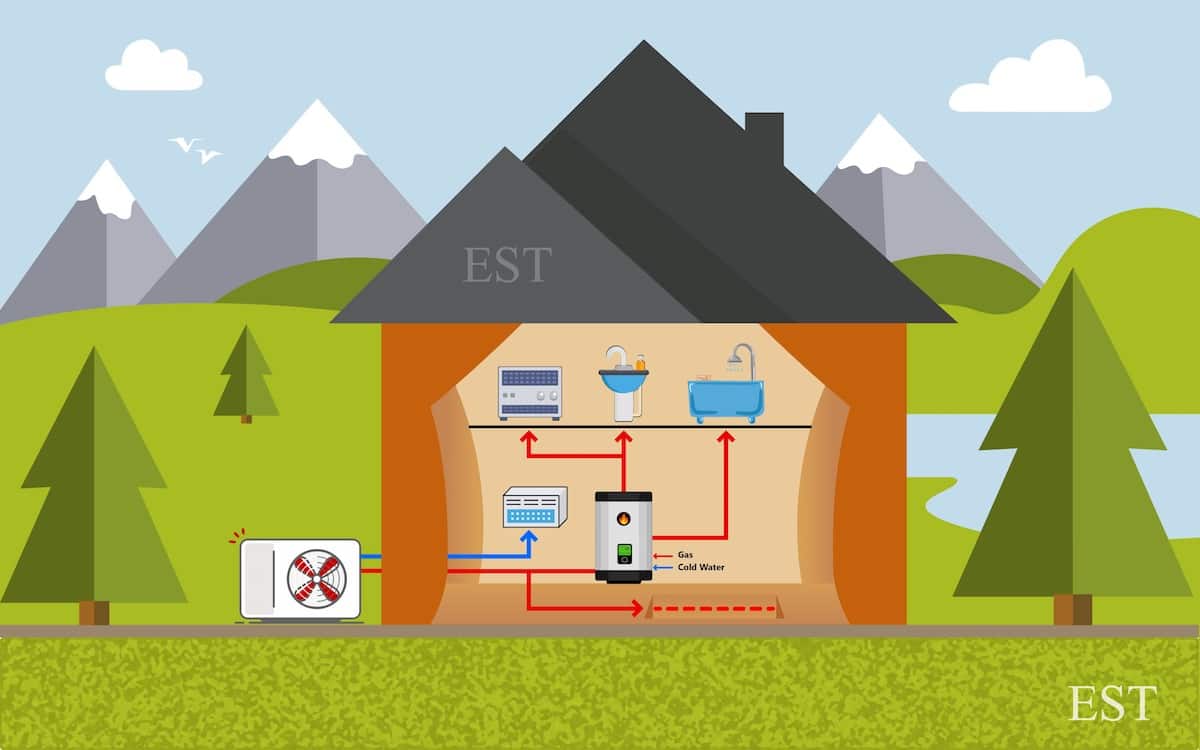

Air-Water Heat Pump

This type transfers heat to a heating circuit or a tank of hot water. Floor heating is the most common and efficient application of air to water heat pumps. They can also transfer heat into a domestic hot water tank for use in showers and hot water taps of the building. However, ground-water heat pumps are more efficient than air-water heat pumps. This is because the ground temperature several feet beneath the surface is constant throughout the year, unaffected by the outside weather conditions. Therefore, ground to water heat pumps are often a better choice but they cost more to install.

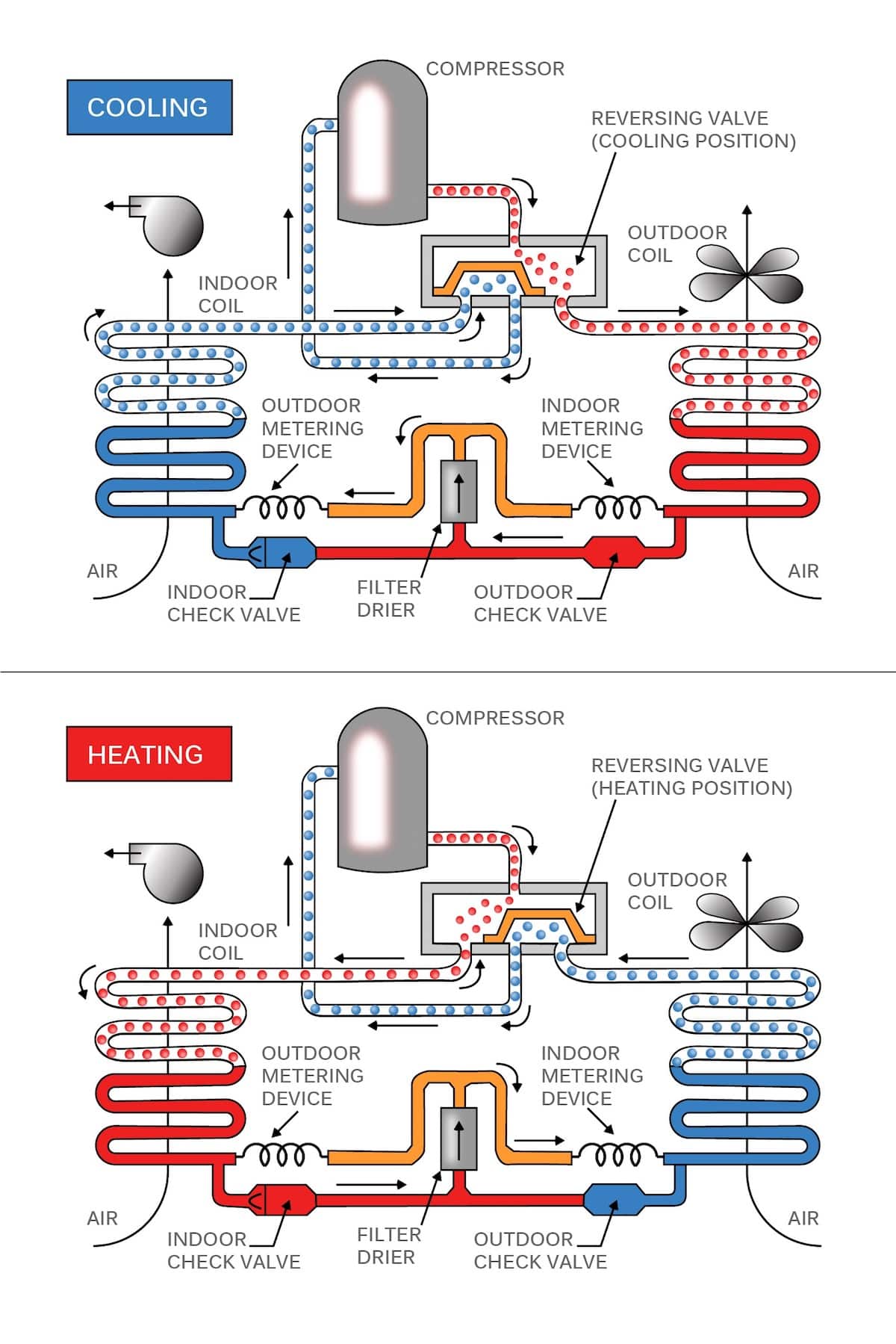

Air Source Heat Pump System Diagram

Below is the wiring diagram for ASHPs. In cooling mode, the indoor coil acts as an evaporator and the outdoor coil as a condenser. In this mode, the compressor receives cool, low-pressure refrigerant vapour. It then increases the pressure hence the temperature of the gas. The hot, high-pressure gas travels through the reversing valve to the outdoor coil, that is the condenser. The fan blows the outside air on the condenser which in turn reduces the temperature causing the refrigerant to condense into a liquid. The refrigerant now cooler but still under high pressure passes through the indoor expansion valve (check valve) where it drops the pressure and temperature. The colder refrigerant now starts evaporating and collecting heat from the room air. In addition, the cold evaporator collects moisture which provides dehumidification for the home. The refrigerant then travels back to the compressor where the process is repeated over again. In the heating mode, the process is reversed.

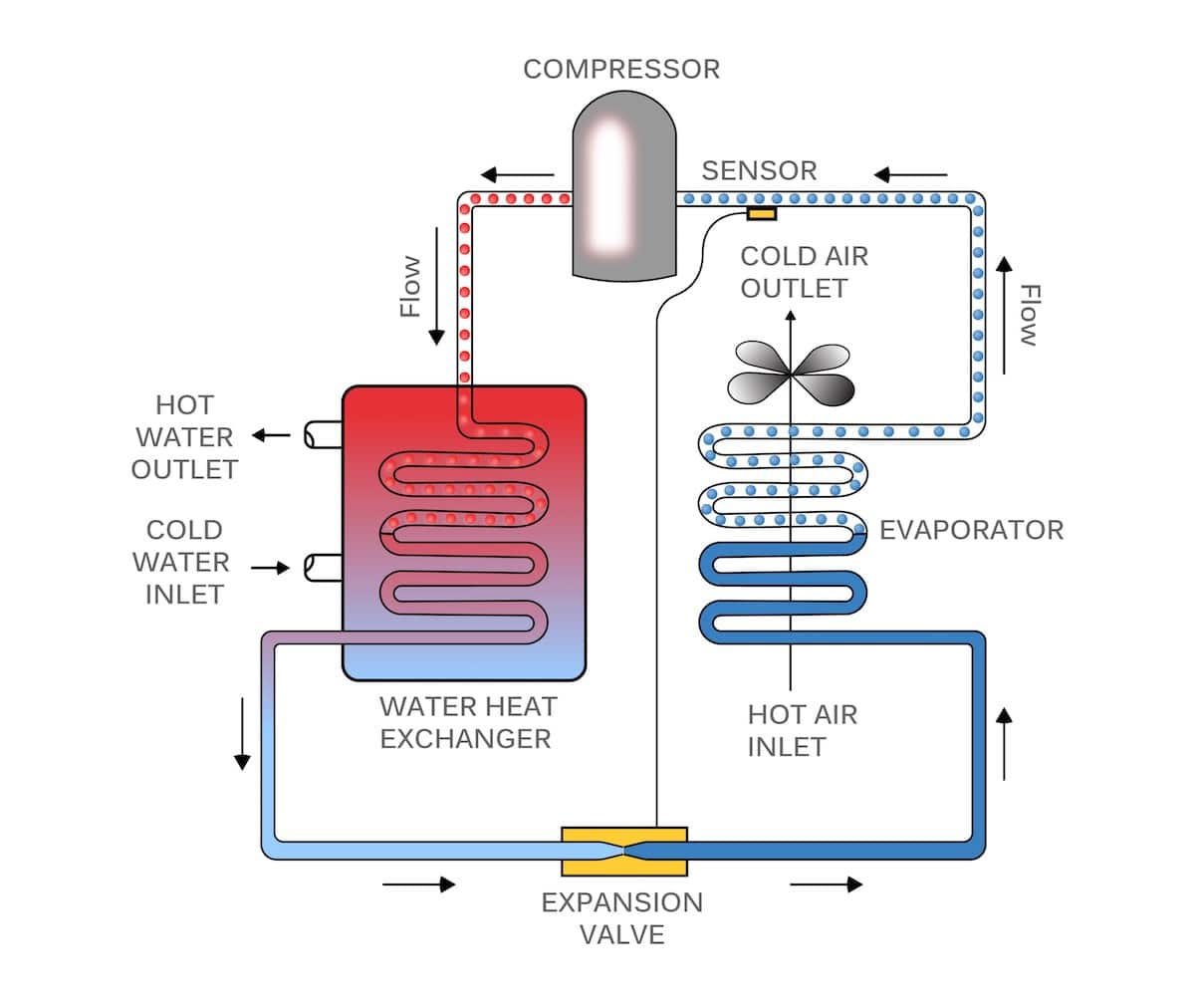

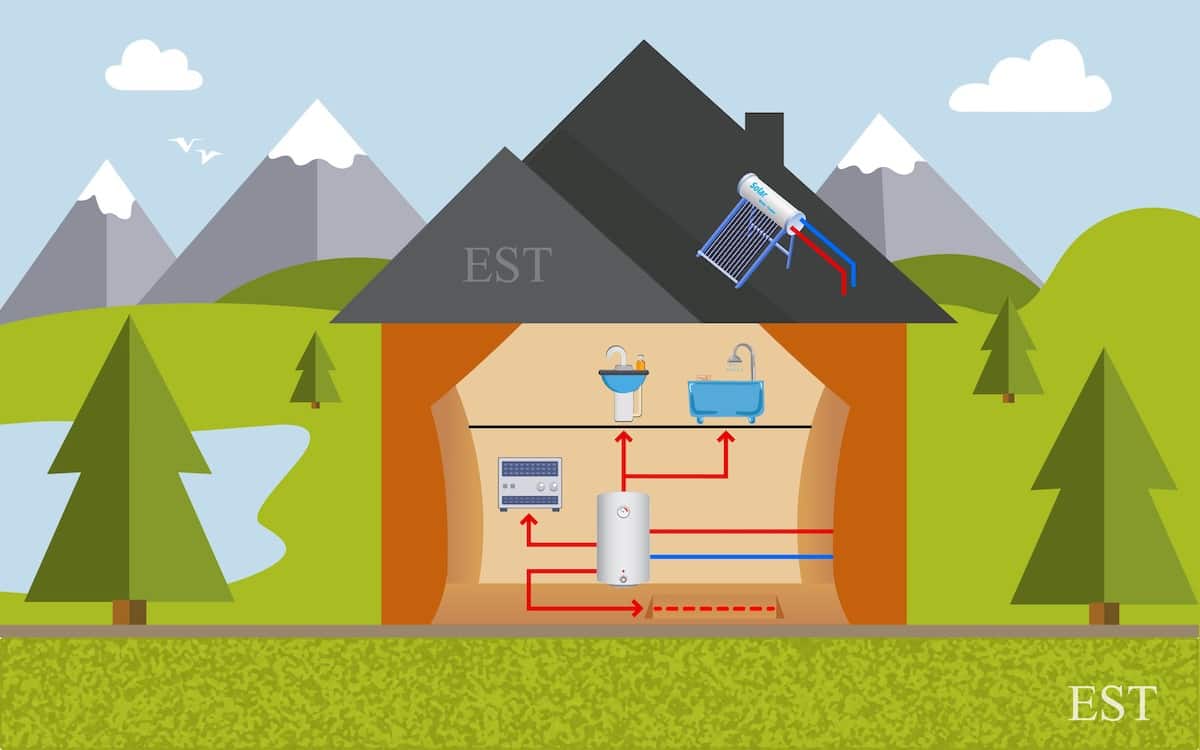

Heat Pump Water Heaters

Besides heating the indoor air, heat pumps can be used for water heating. Example use cases are floor heating and domestic hot water. These heat pumps use water as the heat source and sink for cooling and heating. Heating/cooling changeover can be done in the refrigerant circuit, but it is often more convenient to perform the switching in the water circuits.

Operation Principle

Heat pump water heater transfers heat from the indoor/outdoor air to the water in the tank with the help of a substance called a refrigerant. As it cycles through the system, the refrigerant undergoes variations in temperature and pressure as well as alternating between liquid and vaporous states. Let's examine the 4 states of the refrigerant as it cycles through the system:

- In the beginning, the refrigerant is in a cold, low pressure, liquid gaseous state flowing through tubes that are exposed to room air. It's colder than the room air so the heat in the air moves to the refrigerant. This because heat always moves from warmer things to cooler things. To facilitate the heat transfer the tubes with refrigerant are connected to an evaporator - a heat exchanger much like a car radiator with many fans designed to increase the heat absorption from the warm air into the cold refrigerant. A fan amplifies the absorption by increasing the flow of room air over the evaporator. The heat added to the refrigerant causes its temperature to rise and the fluid becomes warm, low-pressure vapour. As the refrigerant changes from liquid to gas large amounts of energy transfer takes place. Once the refrigerant passes through the evaporator it transforms into a warm gas from a cold liquid. However, the refrigerant is still not hot enough to heat the water so that's where the compressor comes in.

- The compressor raises the pressure of the gas which also raises its temperature. Once it is hot enough the heat will flow from the refrigerant to the water. The compressor next forces the now high-temperature, high-pressure further along the cycle into another heat exchanger called the condenser.

- The condenser is in contact with the water and the hot gas which now gives up its heat to the colder water. As heat leaves the gas refrigerant it cools off below its condensation point and changes from a gaseous state to a high-pressure liquid state. The changes from a gas to liquid facilitates the large transfer of heat energy to the water.

- Finally, the now cooler, high-pressure liquid refrigerant passes through an expansion valve. As the refrigerant passes through the valve its pressure and temperature are greatly reduced. Now cold and in a mixed vapour-liquid state, the refrigerant is once again ready to absorb heat from the room air and repeat the cycle.

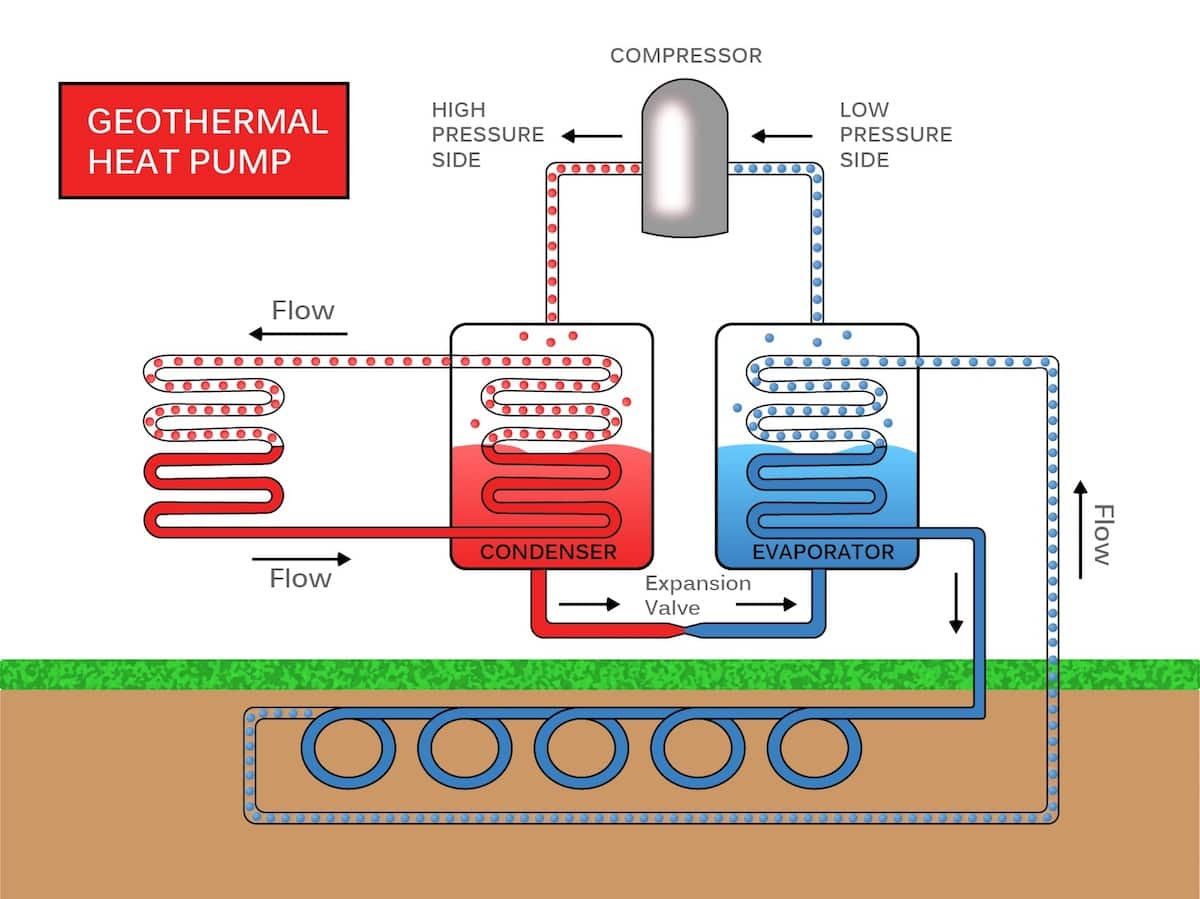

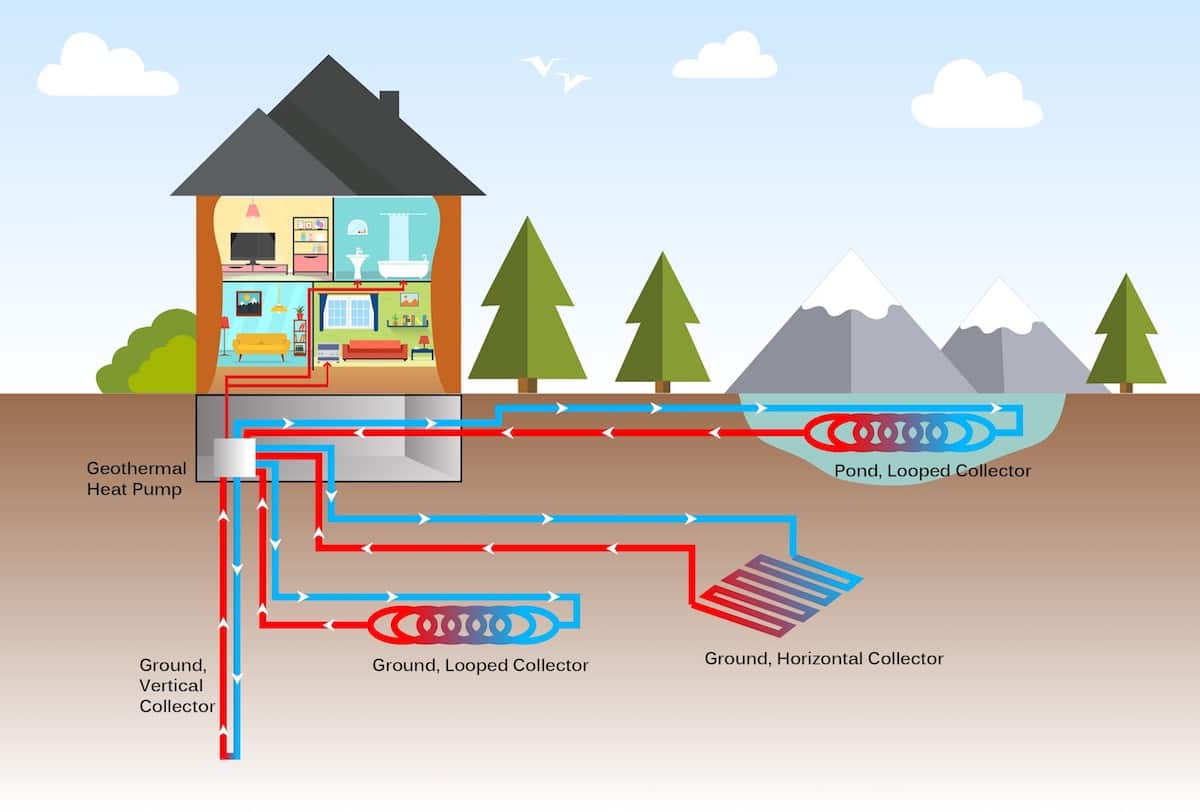

Ground Source Heat Pumps

GHSPs use the ground as a heat source and sink. A heat pump may have a refrigerant-to-water heat exchanger or may be a direct expansion (DX). In systems with refrigerant-to-water heat exchangers, a water or antifreeze solution is pumped through horizontal, vertical, or coiled pipes embedded in the ground. In case of a direct-expansion ground-coupled heat pump, the refrigerant circulates through copper tubing placed in the ground. It is a closed-loop, refrigerant-based geothermal system. DX systems are the most energy-efficient, environmentally clean & cost-effective HVAC systems in the market according to the US Environmental Protection Agency (EPA). That's because of the following factors:

- DX does not require electrical circulators (pumps) thus no additional electricity costs

- DX only requires one heat transfer

- DX systems rely on copper piping which has superior heat transfer properties compared to the plastic tubing used in water-based geothermal systems

How does a geothermal heat pump work?

All heat pumps have a compressor and an expansion valve that manipulate the refrigerant. A refrigerant has 2 stages: gaseous and liquid. Refrigerants work on the basic principle that if you raise the pressure you raise the temperature. Conversely, if you lower the pressure you lower the temperature. This is all done with a compressor and an expansion valve. Let's go through one full cycle of a refrigerant starting from its gaseous state beneath the ground surface. The refrigerant then enters the compressor at 30°F The compressor compresses the gas and increases the temperature to 160°F. The refrigerant travels to a coil where a fan blows across it. The air blowing on the coil absorbs the heat and distributes it throughout the home. As the refrigerant leaves the coil it condenses back to its liquid state moves towards extension valve at 85°F. The expansion valve is basically like a dam with a small hole. When the refrigerant passes through the expansion valve the pressure rapidly decreases and the temperature falls to 20°F. It then travels to thermostatic expansion valves (TXV). These valves control the amount of the refrigerant distributed to each ground loop. The refrigerant is then piped out of the well field and down the vertical boreholes where it begins its transformation back to a gas. As it transforms to its gaseous state it absorbs heat energy from the Earth and travels back to the compressor where this ingenious process is then repeated. When cooling is desired this process is reversed.

Efficiency

For each unit of electric energy used by the geothermal heat pump 3 - 4 units of thermal energy are captured and transferred. Effectively, this means that a well-installed ground source heat pump can be 300% - 400% efficient in terms of its energy use. This level of efficiency also means lower carbon emissions. For example, compared to a gas boiler heating system GHSP has 70% lower carbon dioxide emissions. If the electricity were to come from the Sun, for instance, the system could be carbon-neutral.

Geothermal Heat Pump Cost

Many variables come to play when trying to estimate the cost of geothermal heat pumps. It depends on the type of loop system - vertical, horizontal, or tipi style/slant configuration; soil type; home square footage, etc. A typical house of 2.5k sq f, with heating/cooling loads of 60k BTU, will cost around $20k - $25k to install. This is about double the cost of conventional HVAC system installation but a geothermal heat pump can cut down the half of your utility costs on average. To reduce your initial costs you should definitely check if you are eligible for 30% federal tax credit or other rebates & incentives before pulling the trigger on heat pumps.

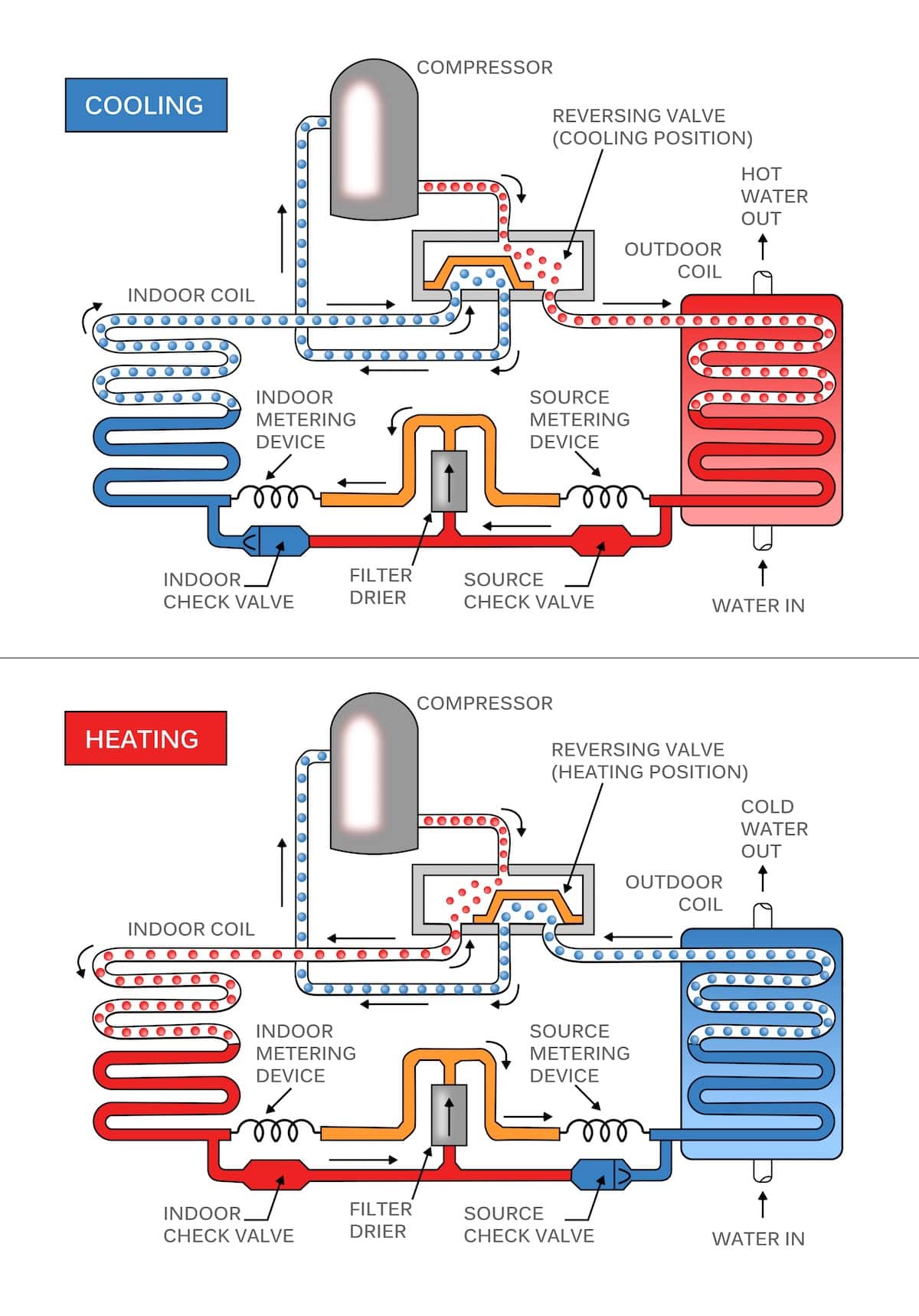

Water Source Heat Pumps

Water-to-air heat pumps rely on water as the heat source and sink and use air to transmit heat to or from the conditioned space. City water is seldom used because of cost and municipal restrictions. Groundwater (well water) is particularly attractive as a heat source because of its relatively high and nearly constant temperature. Water temperature depends on source depth and climate, but, in the United States, generally ranges from 5°C in northern areas to 21°C in southern areas. Sub-types of water source heat pumps include:

Groundwater Heat Pumps

GWHPs use groundwater from wells as a heat source and/or sink. They can either circulate source water directly to the heat pump or use an intermediate fluid in a closed-loop, similar to the ground-coupled heat pump. A groundwater heat pump passes groundwater from a nearby well through the heat pump's water-to-refrigerant heat exchanger, where it is warmed or cooled, depending on the operating mode. It is then discharged to a drain, stream, or lake, or is returned to the ground through a reinjection well.

Many state and local jurisdictions have regulations about the use and discharge of groundwater. Because aquifers, the water table, and groundwater availability vary from region to region, these regulations cover a wide spectrum.

Surface Water Heat Pumps

SWHPs use surface water from a nearby lake, pond, stream, or canal as a heat source or sink. As with ground-coupled and groundwater heat pumps, these systems can either circulate source water directly to the heat pump or use an intermediate fluid in a closed-loop. After the water passes through the heat pump heat exchanger, it is returned to the source or a drain several degrees warmer or cooler, depending on the operating mode of the heat pump. Closed-loop surface water heat pumps use closed water or brine loop that includes pipes or tubing submerged in the surface water (river, lake, or large pond) that serves as the heat exchanger. The adequacy of the total thermal capacity of the body of water must be considered.

As discussed above, notwithstanding the water source (groundwater or surface water), water source heat pumps can be either closed-loop (pond, river) or open-loop (aquifer, river). The closed-loop variation sends a mixture of water and antifreeze to collect thermal energy from a pond or river and transfers it through the heat exchanger. The same mixture is then sent around again to repeat the cycle. The open-loop variations pull in freshwater from an aquifer or river and pump it into the heat exchanger to collect the heat. Once it passes through the water is then released into the same water source.

Exhaust Air Heat Pumps

Exhaust air heat pumps extract heat from the exhaust air of a building via the ventilation system and then transfers that heat to the supply air. This way you reuse the heat that would otherwise be lost to the outside air to heat indoor air or domestic water. Heat recovery pumps operate in a similar manner to other heat pumps such as air or ground source heat pumps and are suitable for providing hot water and heating for single/multi-apartment buildings. Exhaust air ventilation systems are more commonly used in conjunction with underfloor heating systems and have been used extensively in Germany and Sweden.

Operation Principle

The system works by tunnelling heated air through a series of ventilation ducts from moisture-producing spaces like bathrooms, utility rooms or kitchens. The hot air is blown over a heat exchanger which then transfers the heat energy to the refrigerant. The refrigerant boils and evaporates. It is then passed to a compressor where it is heated up and transfers that heat to the water or incoming air.

As a series of ducts are required through the building to allow the flow of air to and from the exhaust air heat pump, installation tends to be carried out during the original construction of buildings. This is because retrofitting into existing buildings is not practical or cost-effective.

Pros and Cons

In addition to the advantages that all heat pumps offer, exhaust air heat pumps offer some additional benefits:

- contributes to compliance with building regulation requirements

- building's continuous ventilation which enhances the indoor air quality and prevents condensation

Here are the major cons

- Installation costs can be high because of the additional ductwork

- Retrofitting can be even more expensive and disruptive

- They heat the water to lower temperatures than traditional radiators but it still makes them suitable for underfloor heating

- The efficiency can be significantly compromised by poor installation, incorrect commissioning, and wrong operation.

Hybrid Heat Pumps

Hybrid or twin-source heat pumps can use both air source heat pump and a furnace interchangeably. They are a fuel-saving alternative to heating and cooling systems. When outdoor air is above -4°C, (25°F) they use air otherwise oil or gas furnace is put to work. An air-source heat pump can be added to new or existing gas- or oil-fired furnaces. This unit, typically called an add-on, dual-fuel, or hybrid heat pump normally operates as a conventional heat pump. During extremely cold weather, the refrigerant circuit is turned off and the furnace provides the required space heating. These add-on heat pumps share the air distribution system with the warm-air furnace. The indoor coil may be either parallel to or in series with the furnace. However, the furnace should never be upstream of the indoor coil if both systems are operated together.

Special controls are available that prevent simultaneous operation of the heat pump and furnace in this configuration. This operation raises the refrigerant condensing temperature, which could cause compressor failure. In applications where the heat pump and furnace operate simultaneously, the furnace and heat pump indoor coil must be arranged in parallel, or the furnace combustion and flue passages must be designed to avoid condensation-induced corrosion during cooling operation. The furnace and heat pump often operate simultaneously during the heat pump's defrost mode to regulate air temperature.

Solar Heat Pumps

Solar energy may be used either as the primary heat source or in combination with other sources. Air, surface water, shallow groundwater, and shallow ground-source systems all use solar energy indirectly. The principal advantage of using solar energy directly is that, when available, it provides heat at a higher temperature than the indirect sources, increasing the heating coefficient of performance. Compared to solar heating without a heat pump, the collector efficiency and capacity are increased because a lower collector temperature is required.

Solar assisted heat pump relies on low-temperature solar energy as the heat source. Solar heat pumps may resemble water-to-air, or other types, depending on the form of solar heat collector and the type of heating and cooling distribution system. solar heat pump for pool, solar-assisted heat pump water heater, solar heat pump air conditioner, solar-powered underfloor heating.

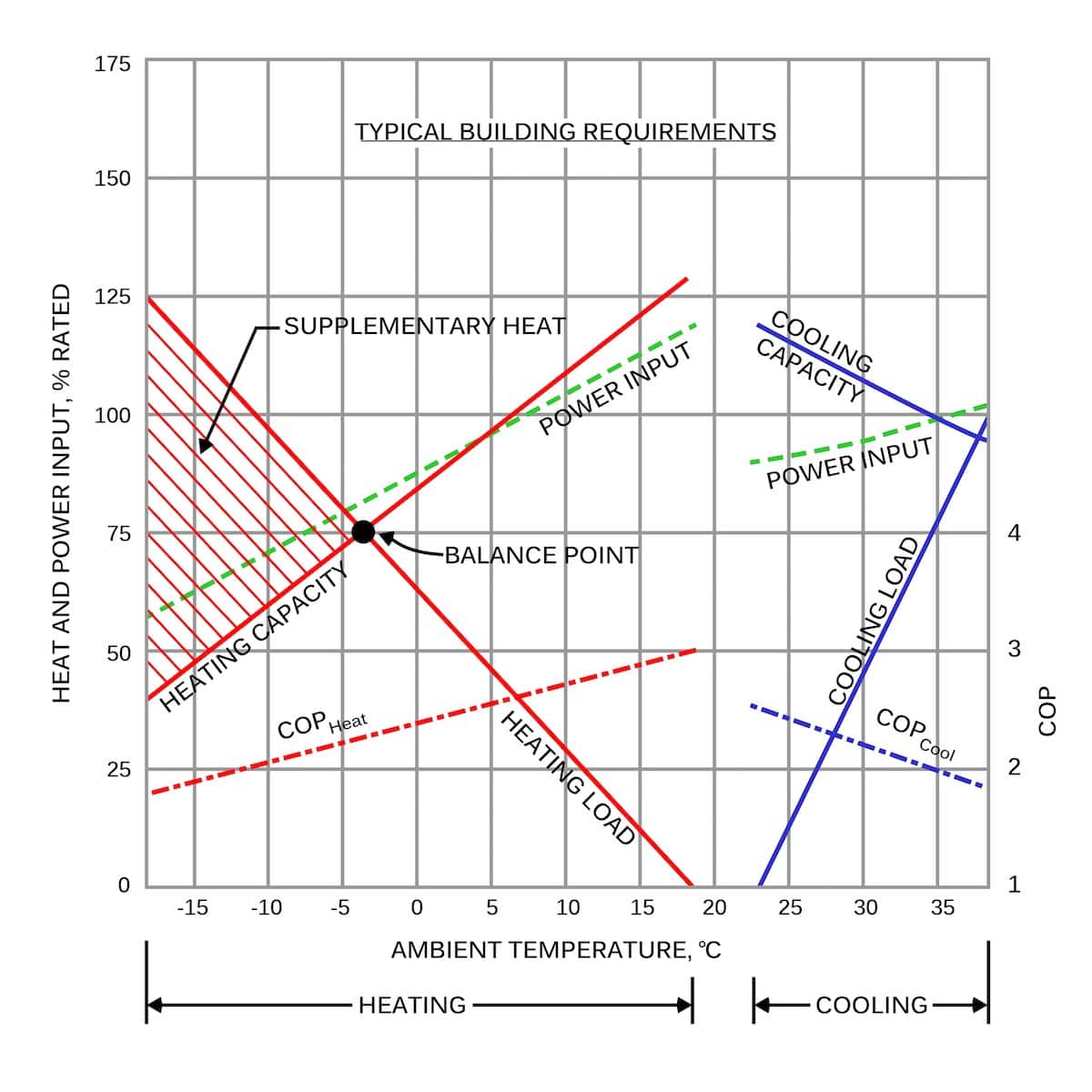

Heat Pump Efficiency Chart

The above heat pump temperature efficiency chart shows performance characteristics of a single-speed, air-source heat pump, along with heating and cooling loads for a typical building. Heat pump heating capacity decreases as ambient temperature decreases. This characteristic is opposite to the trend of the building load. The outdoor temperature at which heat pump capacity equals the building load is called the balance point. When the outdoor temperature is below the balance point, supplemental heat (usually electrical resistance) must be added to make up the difference, as shown by the shaded area. The coefficient of performance (COP) shown in the above figure is for the refrigerant circuit only and does not include supplemental heat effects below the balance point.

The building's balance point can be lowered by improving the thermal performance of the space by doing a home energy audit or by choosing a heat pump larger than the cooling load requires. Excessive oversizing of cooling capacity causes excessive cycling, which results in uncomfortable temperature and humidity levels during cooling.

Heat Pump vs Furnace

Heat pumps are a better choice for homes in moderate climates but they struggle in extreme hot or cold temperatures when furnaces perform better. But it is not "either this or that" choice. Heat pump furnace combinations or hybrid heat pumps are available that allow switching to oil or gas furnace when outdoor temperature gets too high or too low for the heat pumps to operate normally. Heat pumps with electric (oil) furnace backup also exist. But if you have to choose one over the other then here are some factors to note:

Heat pumps are:

- more efficient. They also transfer heat instead of creating it so they need less energy

- more cost-effective because they don't depend on fuels as opposed to furnaces

- quieter than furnaces so there's very little or no noise pollution

- safer because there's no risk of carbon monoxide poisoning or oil/gas fire

- used for both space heating and cooling

Furnaces:

- require less maintenance compared to air source heat pumps

- are more dependable because they have fewer mechanical components

- heat your home in any weather conditions

- lower installation costs.

Advantages & Common Problems

Pros

- Heat pumps save you money. They are cheaper to run than direct electric heaters, oil boilers, burning coal, LPG or gas. This is before various governmental incentives or rebates are applied

- Heat pumps require less maintenance than biomass boilers or other combustion-based heating systems. This is because their operation can be fully automated

- Heat pumps save space. They have no fuel storage requirements

- Independent source of heating. No reliance on 3rd party fuel providers

- Heat pumps are safe. There is no combustion involved and no potentially dangerous emissions.

- They have a longer lifespan than combustion boilers. For example, the ground heat exchanger element of a ground source heat pump installation has a designated life of 100 years.

- Heat pumps reduce carbon emissions. Unlike conventional boiler-based heaters, they produce no on-site carbon emissions. If coupled with a renewable source of energy they can be fully emission-free.

- They require no planning permission.

- They are silent and unobtrusive.

- They serve for both cooling and heating.

- They increase your property value. A well-designed heat pump system is likely to increase the sale value of your property.

Common Problems

Freezing up in winter

Air source heat pumps will develop frost or ice on outdoor coils in cold weather. Here's how it happens: in order to absorb heat, the evaporator on the outside unit must operate at temperatures lower than the outside air. This very low operating temperature allows ice or frost to accumulate on the outside of the evaporator. But this is not a con as such because heat pumps with defrost cycle exist. During the defrost cycle the reversing valve reverses the refrigerant path back to that of the summer mode. This allows the inside heat to be transferred from inside airstream to the outside coil thereby melting the accumulated frost.

Freezing up in summer

If either the indoor or outdoor unit is freezing up in summer it could be due to a refrigerant leak, clogged filter or dirty coils that are preventing normal heat transfer.

Sudden loss of heat

In this situation first try out the following steps to fix the problem:

- check the thermostat to see if the heat pump is turned on and set to heat mode.

- If it's not the thermostat then the problem may be a lack of power caused by a tripped circuit breaker. Check your home's circuit breaker and reset it if that's the case.

- If the problem is still there then perhaps you've recently replaced your thermostat? If that's the case then the new thermostat may either be the wrong type (is it made for heat pumps?) or the wrong wiring could be the culprit

- If the problem persists then contact HVAC specialists to investigate and fix the issue

Runs constantly in cold weather

Make sure the heat pump is not set on cooling mode and the thermostat temperature is set correctly. Otherwise, constantly running heat pump in cold weather may not be an issue because heat pumps are designed to have longer running times and put out less heat in a unit of time as compared to a furnace. On the other hand, if the outside temperature is above 32° F (0° C) and the heat pump is still running all the time you could have a service issue such as leaking refrigerant, frozen outdoor unit or compressor problem.

Not heating adequately

The possible reason could be

- an undersized unit that's not equipped properly enough to heat the space

- poorly insulated space which causes much of the produced heat to be wasted

- lack of maintenance (dirt build-up, clogged filters)

Running constantly in summer

Your heat pump might run continuously in summer to reach a low set temperature in, particularly hot weathers. But if it's not very hot and your heat pump operates non-stop you probably have cooling problems. Before you reach out for a phone, make sure the thermostat is set correctly. Also, check the Troubleshooting section below.

Blowing cold air

If the heat pump is working in heating mode but the air coming from the vents is cold there may be a problem with your system's thermostat or air handler. This doesn't necessarily mean there's a problem at hand. Remember that the air produced by heat pumps is not as hot as that of a furnace. It may also be the case that the heat pump is temporarily in the defrost mode to prevent icing up. In this mode, it can temporarily output cold air.

If you've checked everything but the air from the vents is still colder than usual try setting the thermostat to emergency heat. Make sure the thermostat is set to 5 degrees above the room temperature. If the air becomes warmer than you have a faulty outdoor unit if not you may have a defective thermostat or air handler. Other possible causes of cold air include defective compressor valve or refrigerant flow issues.

Troubleshooting

Some troubleshooting steps you can take are:

- checking the unit's filter to see if it's clogged or damaged. Clean dirty filters or replace them if necessary.

- checking the indoor air vents and registers to make sure they are not blocked by other objects like furniture, boxes, etc

- clean away the accumulation of dirt, leaves, grass or snow that could potentially be interfering with the unit's normal operation.

- checking the overflowing gutters to make sure they are not dripping onto the outdoor unit.

- check for refrigerant leaks. The grime on the coils can erode the metal and make holes that cause refrigerant leaks. In this case, you need a service visit.

Common Questions

What temperature is a heat pump not effective?

Geothermal heat pumps have a steady coefficient of performance (COP). That is to say, their effectiveness doesn't decline with outdoor air temperature drop because their heat source (the ground) never fluctuates in temperature. For the air source heat pumps the cut off temperature is around -5° F (-20°C).

Do you really save money with a heat pump?

Heat pumps have efficiency rates of over 300% compared to traditional electric heaters. If you are using a heat pump along with a primary heating system such as oil, gas or electric, you'll find extra savings by using the heat pump to offset the primary fuel use.

Is a heat pump worth it?

When it comes to cooling, heat pumps are equivalent to the same size AC. If you're planning to replace an air conditioner that's 10 - 15 years old, you'll most likely have cooling that's better and less expensive with heat pumps. Additionally, heat pump systems have higher energy efficiency than furnaces because they draw electricity to transfer the heat rather than creating it with electrical resistance. This makes heat pumps 3 - 4 times more energy efficient in heating mode than electric furnaces.

What is the best heat pump on the market today?

Please see our section on Best Mini-Split Heat Pumps.

How long will a heat pump last?

It depends on factors like the heat pump type, geographical location, and the insulation level of the space. Geothermal heat pumps have a 100-year lifespan. Air source heat pumps will last around 15 years. The lifespan also depends on the maintenance (cleaning the coils and filters, fins on the outside unit).

How efficient is a heat pump?

In moderate climates where heating and cooling needs are not demanding, heat pumps offer an energy-efficient alternative to furnaces and air conditioners. A modern heat pump can twice reduce your electricity usage for heating compared to electric resistance heating such as furnaces and baseboard heaters.

Should my heat pump run all the time?

In winter your heat pump will run longer cycles depending on the outdoor temperatures. If the temperature falls below 30° F it may run continuously throughout the day. When this happens don't turn it off and don't set it on emergency heat mode. In this mode what you actually do is you turn off the heat pump and switch over to the more expensive back-up furnace (toaster coils).

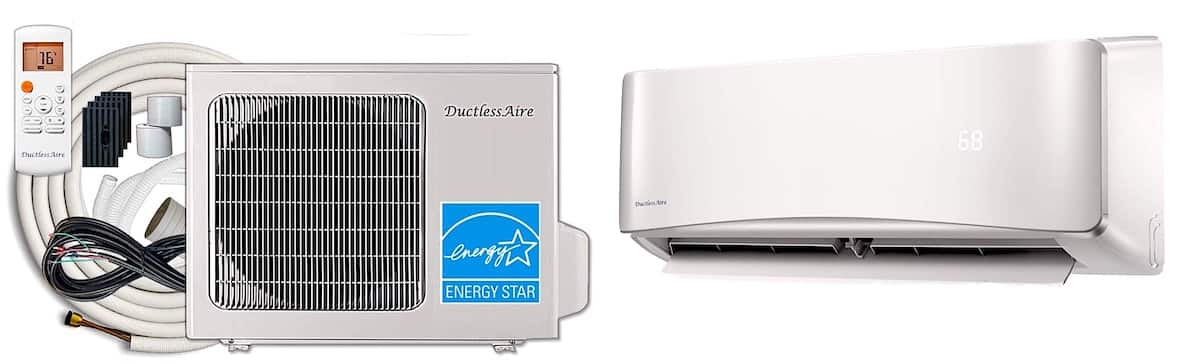

Best Mini-Split Heat Pumps of 2019

Before we dive into the list of the best heat pumps of 2019 let's learn about an efficiency metric for rating heat pumps called SEER. It stands for seasonal energy efficiency ratio and measures air conditioning and heat pump cooling efficiency. It is calculated by the cooling output for a time range divided by the total electric energy consumption during the same time frame. For a heat pump, SEER rates its cooling efficiency. For heating efficiency, another metric called HSPF (heating seasonal performance factor) is used. Heat pumps should have a SEER rating of at least 15 to qualify as energy efficient. Higher SEER value means better energy efficiency.

Another thing to check when buying heat pumps is whether the given model supports inverter technology. The advantage of the inverter ACs is that their compressor's motor speed is variable. This is a useful feature because a sensor in the inverter can adjust the power according to the room temperature thus lowering the electrical consumption and saving energy.

Lastly, a bit of trivia about split-ductless heat pumps: the outdoor unit is what referred to as a heat pump and the indoor unit is called air handler. With that in mind, let's proceed to the actual list.

Comments